Packed tower wet scrubber packed tower scrubbers also referred to as packed bed or packed column scrubbers are designed for chemical scrubbing of contaminants from gas streams.

Packed bed wet scrubber design.

They are used.

Tri mer packed bed scrubbers are versatile reliable systems that serve the widest variety of processes.

Monroe environmental is a single source solution for highly durable and efficient packed bed scrubbers.

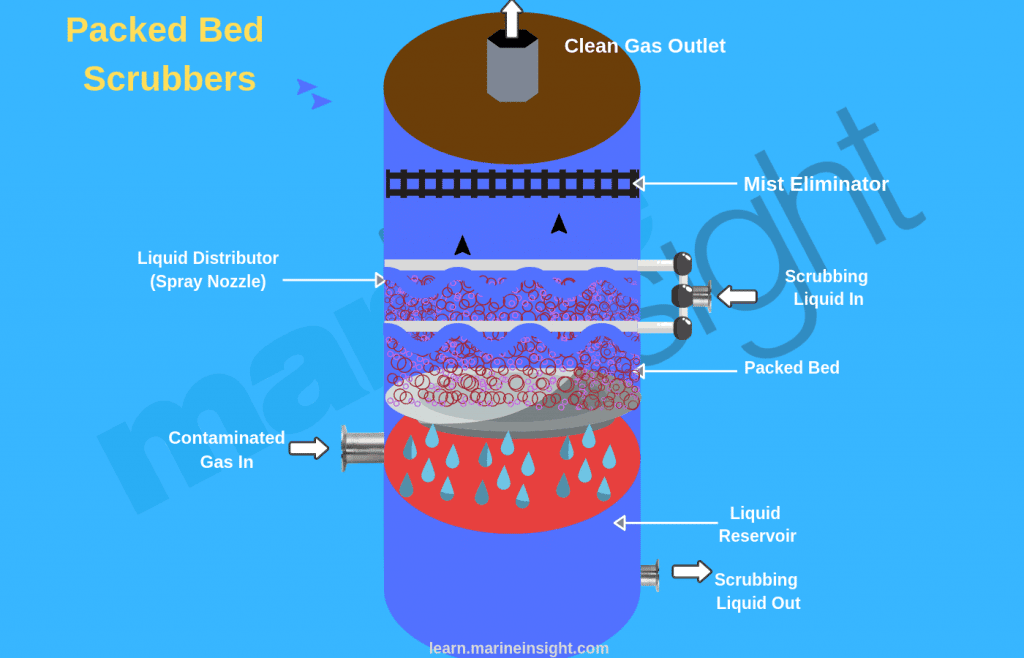

A packed bed scrubber is a wet scrubber that removes acids soluble gasses chemicals fumes and odors.

In this project the efficiencies of cross flow and counter current flow packed bed wet scrubbers used in penang malaysia are studied and compared.

These are generally referred to as low energy scrubbers.

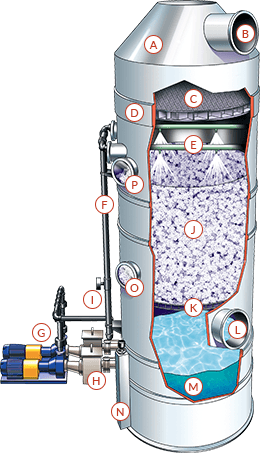

Internal packing in the scrubber housing provides a large wetted surface area to induce intimate contact between the contaminated gas and the scrubbing liquid.

Design requirements for these industry scrubbers are also investigated from department of environment penang.

Efficient removal of inorganic gases odors and fumes and are particularly appropriate where gas streams have extreme ph.

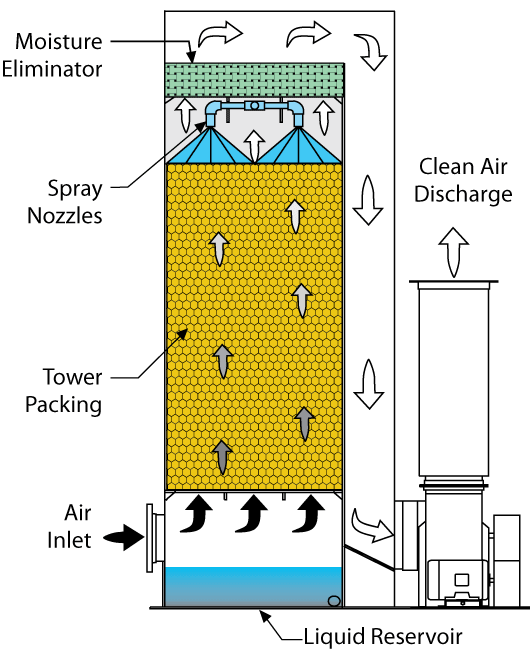

A packed bed tower design where the mist eliminator is built into the top of the structure.

They can collect solids but are not often used for this purpose because wet dust collecting in the beds would require unreasonable maintenance.

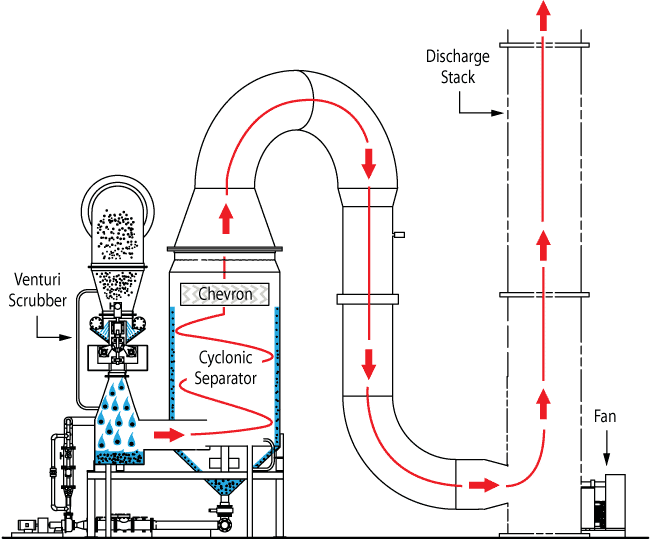

There are several types of wet scrubber designs including spray tower tray type and packed bed wet scrubbers.

The creation of large surface areas can be accomplished by passing the liquid over a variety of media packing meshing grids trays or by creating a spray of droplets.

The common designs of the packed bed scrubber are cross flow and counter current flow.

Various tower designs exist the design of wet scrubbers or any air pollution control device depends on the industrial process conditions and the nature of the air pollutants involved.

Air pollution control expertise.

The absorption of gases takes place in the scrubber s random packing section and scrubbing liquid is introduced in a liquid trough or spray distribution system.

Contaminated gas flows through a specially designed packing media that is wetted with recirculated liquid.

We will evaluate your application requirements to determine the optimum design parameters a custom solution for your plant.

The packing s surface area material shape weight and cost are all important factors for finding a chemically compatible packing that gives maximum gas liquid contact and low gas phase pressure drop.

In the vertical counter current design gas flows upward while scrubbing liquid flows down through banks of sprays.

Tri mer packed scrubbers are highly recommended for the.

Monroe environmental packed bed scrubbers have been used effectively to remove a wide range of air pollutants in many industrial and municipal applications.